Every state has food safety inspections of food service establishments. Their job is fourfold:

1. To prevent the possibility of foodborne illness

2. To educate food service staff about safe food handling practices

3. Ensure these facilities meet basic sanitation requirements

4. Enforce food safety regulations.

While their job is to promote health and serve the public, most restaurants and food service locations fear these unannounced inspections. Instead of fearing them, it would be more appropriate for the establishment to see these inspections as an opportunity to evaluate its health compliance standards.

Frequency of Foor Safety Inspections

The frequency of food safety inspections may vary from state to state. They are usually determined on a risk-based criteria assessment. The more complex the food handling operations of the establishment, the more often the health department will visit. Whereas a smaller establishment, such as a coffee house or small bakery, may only expect an annual visit, a much larger business might expect monthly inspections.

If someone reports your establishment for a foodborne illness or substandard operating procedure, the health department is mandated to perform an inspection. These complaints often result in additional inspections. The frequency will also increase depending on prior scores.

Health inspectors are frequently assigned to one particular area. Even though standard report procedures are available for review, the inspectors have broad discretion in conducting their inspections.

Usually, the establishment will be inspected during regular operating hours. The employees may be informed that an inspection is in process, but the inspector will request to speak with the manager.

The order of inspected areas may vary but will include the front receiving area, the kitchen, walk-ins, freezers, dishwashing and storage areas, service line, buffets, restrooms, dining rooms, bar, waitperson service areas, dumpsters, and parking areas.

What to Expect During a Food Safety Inspection

The style of the inspector may vary considerably. Some inspectors may educate managers on how to correct violations. Others will cite the violation without explanation. Questions and comments should be respected and clarified if necessary. Taking notes will show that you’re taking the inspection seriously and appreciating the constructive comments for further modification of your food handling program.

Some inspectors will allow you to correct violations on-site. These may include quick fixes such as cleaning spray handle nozzles or lowering trash lids. Upon completion, the inspector will review the report with the manager. The report is then left on site and posted to the Health Department’s website, becoming a public record.

The inspectors should be seen as educating and informing the manager of proper food handling requirements, allowing them to correct violations to protect the public from acquiring foodborne illnesses.

Common Food Safety Inspection Items:

• Missing or cracked tiles. Lights protected with plastic shields or plastic tubes, air curtains working at delivery doors, and doorways with air pumps for closure. Floors, floor drains, walls and ceilings are clean and in good repair.

• Containers covered and labeled. Gaskets, fan guards, shelving, and all door handles are clean.

• Thermometers are present in all refrigeration units containing meat, poultry, and seafood. Take random temperatures of hot and cold foods at all stations to ensure temperatures are maintained at the proper levels for cold holding and hot holding.

• Dining room furnishings are in good condition, restrooms are stocked and in working condition, and garbage and trash areas are properly covered and in rodent-proof receptacles. Basements are rodent proof and with adequate lighting.

• Storeroom door closed, everything stored six inches off the floor and away from walls, cans inverted, boxes sealed, no flies or insects in dry ingredients

• Single service items wrapped in original sleeves, to-go boxes inverted, cases sealed closed.

• Can opener and blade clean, containers inverted, utensils stored handles up, clean equipment.

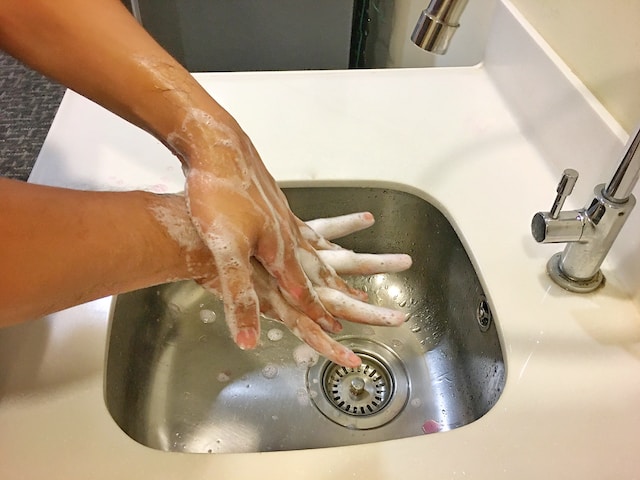

• Hair covered, uniforms clean, aprons on, condition of hands (no cuts, rashes), gloves on, gloves available in assorted sizes.

• Hand sinks clean, hot water of one hundred degrees (F) or more, soap and paper towels available, trash can open with no obstacles in the way.

• Stoves, grills, fryers, vents, hoods, and filters are present and clean; kettles are working.

• No cell phones in work or food areas, no beverages, food, or tobacco in the back of the house

Most Common Violations

Low-risk violations include:

• Nonfood contact surfaces dirty or needs repair

• Aging equipment and cooking utensils

• Improperly stored equipment, utensils, and linens

• Improper maintenance of floors, walls, and ceilings

• Plumbing fixtures need repair

Minor violations: (requiring immediate correction)

• Food left out or stored in unsafe areas

• Inadequate hand-washing facilities

• Improperly labeling and storage of chemical containers

• No rodents, insects, animals, or infestation

• Improper eating, drinking, tobacco, and cell phone use by employees

Major violations:

• Improper hot and cold holding temperatures

• Unsanitary handling of foods

• Improper sanitizing of food contact surfaces

• Communicable diseases of employees

• Improper heating procedures for hot holding

Health department grading systems can vary by jurisdiction. They can be in the form of letter grades, a point system, a pass/fail system, and fines. Be sure you know the system under which you are operating, and the point penalties attached to different violations, as these points determine how your establishment performs during an inspection.

Prepared by Dr. Gary Russotti MD, MS, Idea Boxx- Director of Medical/Biochemical R&D and Regulatory Compliance

Sources: Fitzgerald, M.” Restaurant Health Inspections: How to Make the Grade.” Menu Cover Depot. Feb 2015. P. 1-11.